Major Funding and Strategic Partnerships Drive Sustainability and Precision in Additive Manufacturing

New developments announced on January 24 reveal a maturing technology sector focused on environmental standards and medical precision. EOS has elevated its sustainability commitment while UMass Amherst secured $3.6 million for biofabrication research, this signals a shift toward strict industrial verification.

Industry Shift Toward Certified Production Sets Stage

For over a decade additive manufacturing relied heavily on its reputation for rapid prototyping, yet industrial adoption faced barriers regarding quality assurance and environmental impact. Early claims of sustainability focused on material efficiency often ignored energy consumption, this led to demands for rigorous lifecycle assessments. Manufacturers in aerospace and medicine now require data that rivals traditional semiconductor fabrication, the sector must now prove its viability through certified workflows rather than just novelty. This transition marks a critical evolution where software and governance become as vital as hardware capabilities.

EOS and Universities Launch New Initiatives for 2026

Global laser sintering leader EOS solidified its environmental strategy by becoming a Principal Member of the Additive Manufacturer Green Trade Association. Head of Sustainability Björn Hannappel joined the board effective January 1, this move aligns the company with strict carbon reporting standards for 2045. Meanwhile UMass Amherst secured substantial funding from the Massachusetts Life Sciences Center to advance medical research.

Investment in Precision and Software

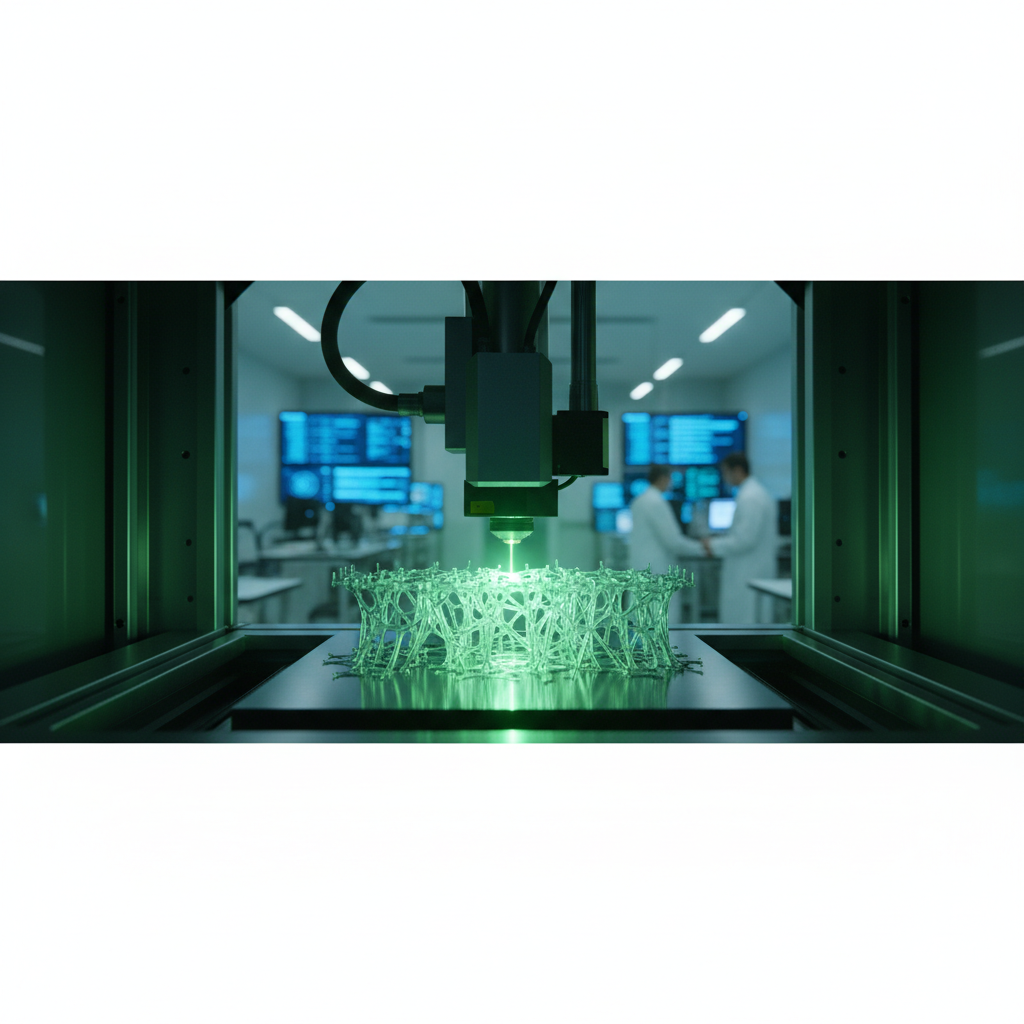

The university allocated $1.58 million for a rare two photon printing system capable of submicron accuracy, this allows researchers to create tissue scaffolds thinner than human hair. On the software front French service bureau MMB Volum-e finalized a three year contract with amsight to digitize quality control. The partnership replaces manual tracking with automated data analysis, reports indicate this could reduce management costs by nearly 70 percent while ensuring full traceability for space grade components.

Medical and Aerospace Sectors to See Immediate Benefits

These advancements fundamentally change how manufacturers bid for contracts in regulated sectors. Aerospace suppliers must now provide carbon data alongside physical parts, this creates a higher barrier to entry for non compliant firms. Medical researchers will leverage the new submicron capabilities to develop personalized implants and organ models, the shift toward digital verification reduces liability risks for companies producing critical life support hardware.

The industry has entered a verification era where software validation holds equal weight to printing speed. Experts predict that regulatory compliance tools will dominate procurement strategies throughout the remainder of 2026.