New Software Integration Between IronRidge and Scanifly Streamlines Residential Solar Planning

Solar installers gained a powerful new tool on Friday as mounting manufacturer IronRidge announced a direct software integration with drone surveyor Scanifly, the partnership links 3D site models with racking engineering to eliminate manual data entry. The move aims to cut design time by up to three hours per project while significantly improving material accuracy.

Rising Soft Costs Drive Demand for Digital Efficiency

The solar industry has long struggled with "soft costs" which include permitting and design expenses that eat into installer margins, historically designers relied on manual methods to transfer measurements from site surveys into engineering tools. This disconnected process often led to human errors and costly corrections during installation, major manufacturers like IronRidge have sought ways to modernize these analog workflows since becoming part of the Enstall group. Meanwhile regulatory shifts now demand higher precision for rapid permitting approvals, the need for interoperability has become urgent as companies look to protect profits amidst fluctuating interest rates.

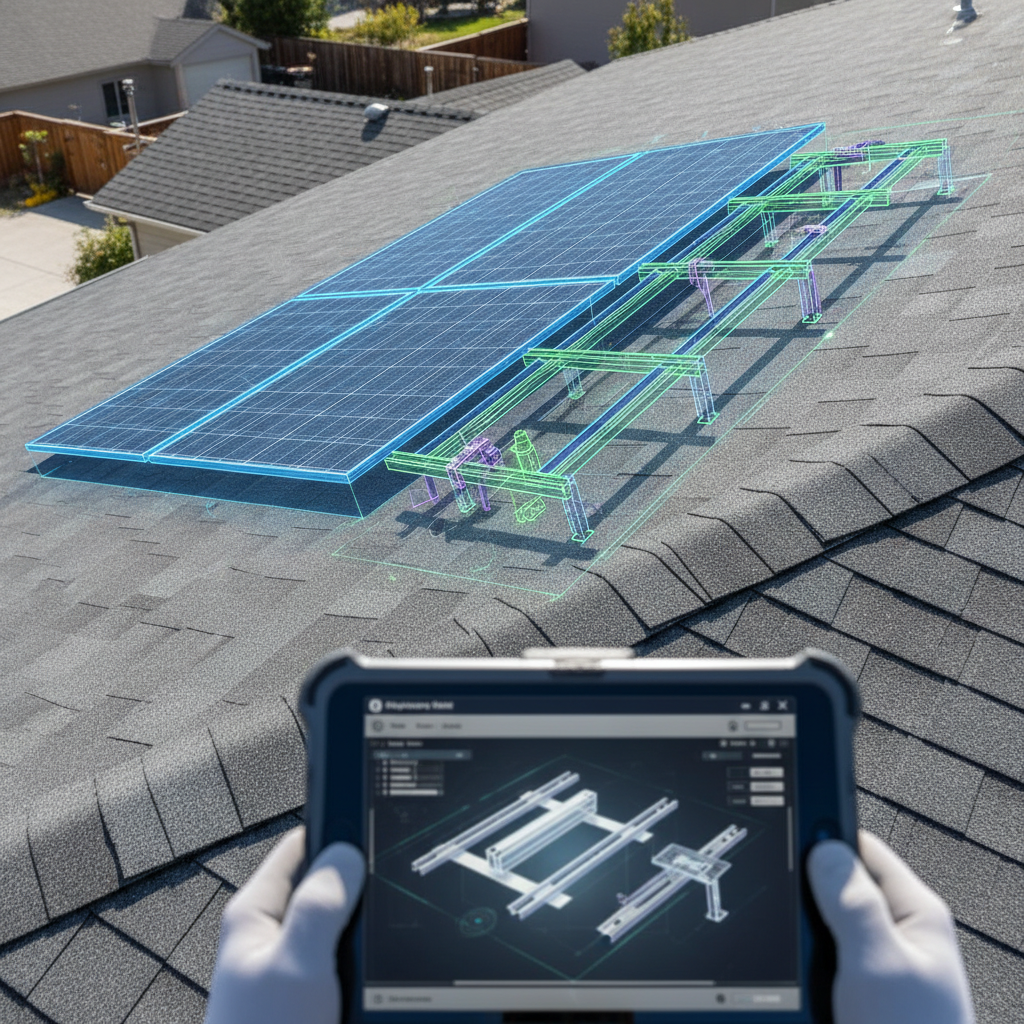

API Connection Links Drone Data to Structural Engineering

The newly announced API integration allows users to export to-scale 3D models directly from Scanifly into the IronRidge Design Assistant, this digital handshake transfers critical data including roof slopes and obstruction locations without requiring manual recreation of the site layout. The system creates a streamlined path for determining necessary hardware, it effectively bridges the gap between field surveys and structural planning.

Automation Reduces Errors and Waste

Once the design data populates in the IronRidge system, the software automatically calculates a precise Bill of Materials based on the exact 3D footprint, this automation supports popular mounting products like the XR and AIRE racking systems. It specifically targets the common problem of "short-ordering" rails where installers arrive at a job site lacking sufficient materials, company data suggests this workflow saves between one and three hours of engineering time for every residential project. The technology effectively replaces guesswork with millimeter-accurate drone measurements, ensuring that the hardware ordered matches the reality of the roof.

Installers to See Reduced Site Visits and Liability

Small and mid-sized contractors stand to gain the most from this technological shift by accessing automated engineering previously reserved for national giants, the integration significantly reduces the need for "truck rolls" caused by design inaccuracies. This protects project margins that are often thin in the current economic climate, safety also improves as drone-based surveys keep workers off roofs during the initial assessment phase. Lowering the time spent on ladders directly reduces insurance risks for installation companies.

This development marks a maturation point for residential solar construction as it moves toward precision manufacturing standards, industry experts anticipate further advancements in AI-driven permitting to follow this integration. Efficient digital workflows are quickly becoming the new standard for competitive installers.